- PRODUCT DETAIL

- MAGNETIC PROPERTIES

- video

- certification

Description of Neodymium Cylinder Magnets N52 D4XH48mm Axial Magnetized Nickel Coating

| Grade | N52 |

| Dimension | D4XH48mm |

| Coating | Ni-Cu-Ni |

| Magnetzied direction | Axial Magnetized |

| Tolerance | ±0.05mm |

| Weight | 4.52g/pc |

| Temperature max | 80°c |

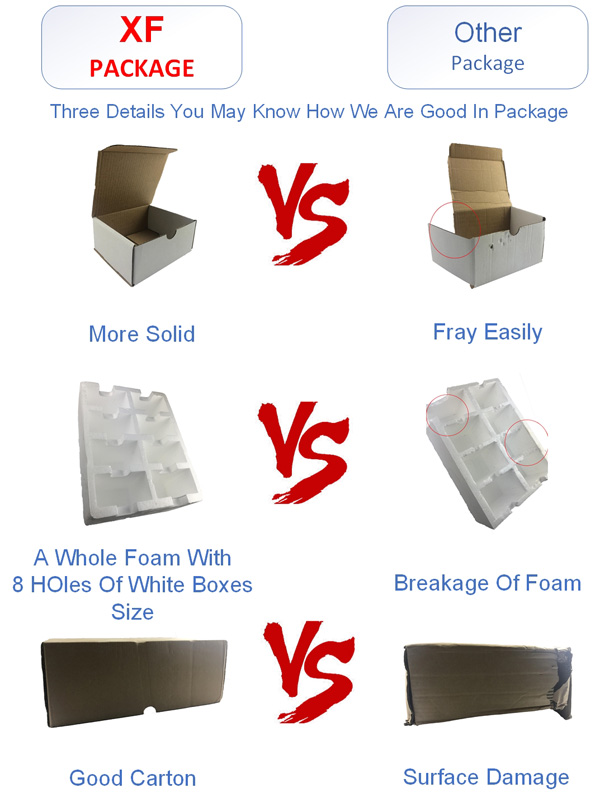

| Package | Vacuum bag + Box + Foam + Carton |

| Shipping | Courier or Sea or Air |

Rare earth neodymium magnets N52 D4x48mm cylinder shape magnets, offer 2.02lb holding force, with central gauss value more than 7000 gauss. This magnet come with strongest grade of N52. With max energy more than 50 KJ/m3, it can continues working within 80 degree, this magnet magnetized in axial direction, which make the polar face on the top and bottom of the cylinder, among the diameter 4mm, the length of 48mm, is almost the largest size we can produce, because the magnet waster already very high for the 48mm long magnets, and magnetize will also be a problem if the length been even more than 48mm. With our client’s requirement, we are making red point on the N pole for the easier recognition. Magnet coating is nickel, with standard thickness of round 20μm. Coating is a protection for the magnets from corruption, specially when the magnet working under wet, salty environment. Working environment and the protection condition for the magnets, is key point to the usage of the magnets. Please feel free to contact us for your better choice of the customized magnets.

Application

Comparison of Products

Comparison of Packaging

MAGNETIC PROPERTIES

| Grade | Residual Induction Br | Coercive Force HcB | Intrinsic Coercive Hcj | Energy Product(BH)max | Max Working Temp. | ||||||||

| Kgs | T | KOe | KA/m | Koe | KA/m | MGOe | KJ/m | L/D≥0.7 | |||||

| Max | Min | Max | Min | Min | Min | Min | Min | Max | Min | Max | Min | ℃ | |

| N35 | 12.30 | 11.80 | 1.23 | 1.18 | ≥10.9 | ≥868 | ≥12 | ≥955 | 36 | 33 | 287 | 263 | ≤80 |

| N38 | 12.60 | 12.30 | 1.26 | 1.23 | ≥11.3 | ≥899 | ≥12 | ≥955 | 39 | 36 | 311 | 287 | ≤80 |

| N40 | 12.90 | 12.60 | 1.29 | 1.26 | ≥11.4 | ≥907 | ≥12 | ≥955 | 41 | 38 | 327 | 302 | ≤80 |

| N42 | 13.30 | 12.90 | 1.33 | 1.29 | ≥11.5 | ≥915 | ≥12 | ≥955 | 43 | 40 | 342 | 318 | ≤80 |

| N45 | 13.70 | 13.30 | 1.37 | 1.33 | ≥11.0 | ≥876 | ≥12 | ≥955 | 46 | 43 | 366 | 342 | ≤80 |

| N48 | 14.10 | 13.70 | 1.41 | 1.37 | ≥10.5 | ≥836 | ≥11 | ≥876 | 49 | 45 | 390 | 358 | ≤80 |

| N50 | 14.50 | 14.00 | 1.45 | 1.40 | ≥10.5 | ≥836 | ≥11 | ≥876 | 51 | 47 | 406 | 374 | ≤60 |

| N52 | 14.80 | 14.30 | 1.48 | 1.43 | ≥10.5 | ≥836 | ≥11 | ≥876 | 53 | 49 | 422 | 390 | ≤60 |

| 35M | 12.30 | 11.80 | 1.23 | 1.18 | ≥10.9 | ≥868 | ≥14 | ≥1114 | 36 | 34 | 287 | 271 | ≤100 |

| 38M | 12.60 | 12.30 | 1.26 | 1.23 | ≥11.3 | ≥899 | ≥14 | ≥1114 | 39 | 36 | 311 | 287 | ≤100 |

| 40M | 12.90 | 12.60 | 1.29 | 1.26 | ≥11.6 | ≥923 | ≥14 | ≥1114 | 41 | 38 | 327 | 302 | ≤100 |

| 42M | 13.30 | 12.90 | 1.33 | 1.29 | ≥12.0 | ≥955 | ≥14 | ≥1114 | 43 | 40 | 342 | 318 | ≤100 |

| 45M | 13.70 | 13.30 | 1.37 | 1.33 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 46 | 43 | 366 | 342 | ≤100 |

| 48M | 14.10 | 13.70 | 1.41 | 1.37 | ≥12.9 | ≥1027 | ≥14 | ≥1114 | 49 | 45 | 390 | 358 | ≤100 |

| 50M | 14.50 | 14.00 | 1.45 | 1.40 | ≥13.0 | ≥1033 | ≥14 | ≥1114 | 51 | 47 | 406 | 374 | ≤100 |

| 35H | 12.30 | 11.80 | 1.23 | 1.18 | ≥10.9 | ≥868 | ≥17 | ≥1353 | 36 | 33 | 287 | 263 | ≤120 |

| 38H | 12.60 | 12.30 | 1.26 | 1.23 | ≥11.3 | ≥899 | ≥17 | ≥1353 | 39 | 36 | 311 | 287 | ≤120 |

| 40H | 12.90 | 12.60 | 1.29 | 1.26 | ≥11.6 | ≥923 | ≥17 | ≥1353 | 41 | 38 | 327 | 302 | ≤120 |

| 42H | 13.30 | 12.90 | 1.33 | 1.29 | ≥12.0 | ≥955 | ≥17 | ≥1353 | 43 | 40 | 342 | 318 | ≤120 |

| 45H | 13.70 | 13.30 | 1.37 | 1.33 | ≥12.3 | ≥979 | ≥17 | ≥1353 | 46 | 43 | 366 | 342 | ≤120 |

| 48H | 14.10 | 13.70 | 1.41 | 1.37 | ≥12.5 | ≥995 | ≥17 | ≥1353 | 49 | 46 | 390 | 366 | ≤120 |

| 35SH | 12.30 | 11.80 | 1.23 | 1.18 | ≥11.0 | ≥876 | ≥20 | ≥1592 | 36 | 33 | 287 | 263 | ≤150 |

| 38SH | 12.60 | 12.30 | 1.26 | 1.23 | ≥11.4 | ≥907 | ≥20 | ≥1592 | 39 | 36 | 311 | 287 | ≤150 |

| 40SH | 12.90 | 12.60 | 1.29 | 1.26 | ≥11.6 | ≥939 | ≥20 | ≥1592 | 41 | 38 | 326 | 302 | ≤150 |

| 42SH | 13.30 | 12.90 | 1.33 | 1.29 | ≥12.4 | ≥987 | ≥20 | ≥1592 | 43 | 40 | 342 | 318 | ≤150 |

| 45SH | 13.70 | 13.20 | 1.37 | 1.32 | ≥12.6 | ≥1003 | ≥20 | ≥1592 | 46 | 42 | 366 | 334 | ≤150 |

| 33UH | 11.80 | 11.40 | 1.18 | 1.14 | ≥10.7 | ≥852 | ≥25 | ≥1989 | 34 | 31 | 271 | 247 | ≤180 |

| 35UH | 12.30 | 11.80 | 1.23 | 1.18 | ≥10.8 | ≥860 | ≥25 | ≥1989 | 36 | 33 | 287 | 263 | ≤180 |

| 38UH | 12.60 | 12.30 | 1.26 | 1.23 | ≥11.3 | ≥899 | ≥25 | ≥1989 | 39 | 36 | 311 | 287 | ≤180 |

| 40UH | 12.90 | 12.50 | 1.29 | 1.25 | ≥11.3 | ≥899 | ≥25 | ≥1989 | 41 | 38 | 326 | 302 | ≤180 |

| 33EH | 11.80 | 11.40 | 1.18 | 1.14 | ≥10.3 | ≥820 | ≥30 | ≥2388 | 34 | 31 | 271 | 247 | ≤200 |

| 35EH | 12.30 | 11.70 | 1.23 | 1.17 | ≥10.5 | ≥836 | ≥30 | ≥2388 | 36 | 33 | 287 | 263 | ≤200 |

| 38EH | 12.60 | 12.20 | 1.26 | 1.22 | ≥11.3 | ≥899 | ≥30 | ≥2388 | 39 | 35 | 311 | 287 | ≤200 |

video

Youtube: https://youtu.be/ZHCYGDpMT28