15 Concepts in Magnetic Materials

1. Hysteresis loop

The hysteresis loop, as shown in the figure, is a characteristic curve of hard magnetic materials like neodymium iron boron magnets. It illustrates the relationship between magnetic induction (B) and magnetizing field strength (H), demonstrating the material’s ability to maintain a strong magnetic field even after the external field is removed.

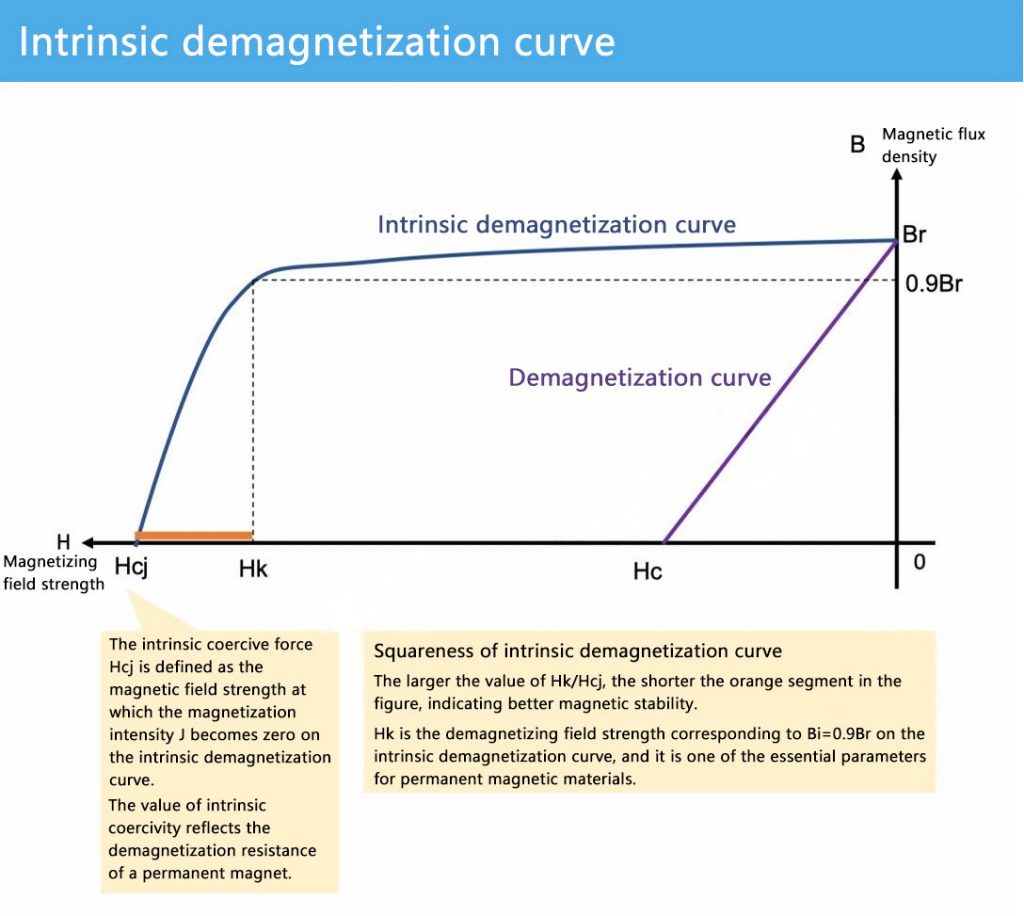

2. Demagnetization curve

When the magnetic field is reversed from O to -Hc, the material becomes completely demagnetized. The magnitude of the coercive force, Hc, required to achieve this state is a measure of the material’s resistance to demagnetization. The purple curve illustrates the demagnetization process.

3. Intrinsic curve and squareness

The intrinsic magnetic induction Bi, also known as magnetization J, is the internal magnetic induction generated in a permanent magnetic material when it is magnetized under an external magnetic field. The curve describing the relationship between the intrinsic magnetic induction Bi (J) and the magnetic field strength H is called the intrinsic demagnetization curve, or simply the intrinsic curve. It reflects the intrinsic magnetic properties of the permanent magnetic material.

The magnetic field strength H corresponding to the point where the magnetization J is zero on the intrinsic demagnetization curve is called the intrinsic coercive force Hcj.

4. Surface treatment – Phosphating

Sintered neodymium iron boron magnets, when exposed to air, will oxidize and corrode. When neodymium iron boron magnets have been in circulation or storage for an extended period and the subsequent surface treatment method is uncertain, a simple phosphating process is generally used as an anti-corrosion treatment. The phosphating process for magnet surfaces involves the following steps: degreasing, water rinsing, acid pickling, water rinsing, surface adjustment, phosphating, and sealing and drying. Commercial phosphating solutions are primarily used in the phosphating process. Phosphated products have a uniform color and a clean surface. They can be vacuum-sealed to significantly extend the storage time, providing a better storage solution compared to previous methods such as oil immersion or coating.

5. Surface treatment – Electrophoretic deposition

Electrophoretic deposition is a process wherein a part is immersed in an aqueous bath containing charged resin particles. Upon application of a direct current, these charged particles migrate towards the oppositely charged electrode and deposit on the part, forming a uniform coating. This process is particularly effective for coating porous magnetic materials, providing excellent adhesion and corrosion resistance to salt spray, acids, and alkalis. However, the coating’s performance in humid and hot environments may be compromised.

6. Surface treatment – Parylene

Parylene, a unique polymer coating, offers unparalleled protection for small and ultra-small magnetic components. Its exceptional properties include:

- Pinhole-free, uniform coating

- Excellent resistance to chemicals, moisture, and corrosion

- Ability to withstand harsh environments

- Compatibility with various substrates

Parylene is deposited in a vacuum, ensuring complete coverage and adhesion to the component’s surface.

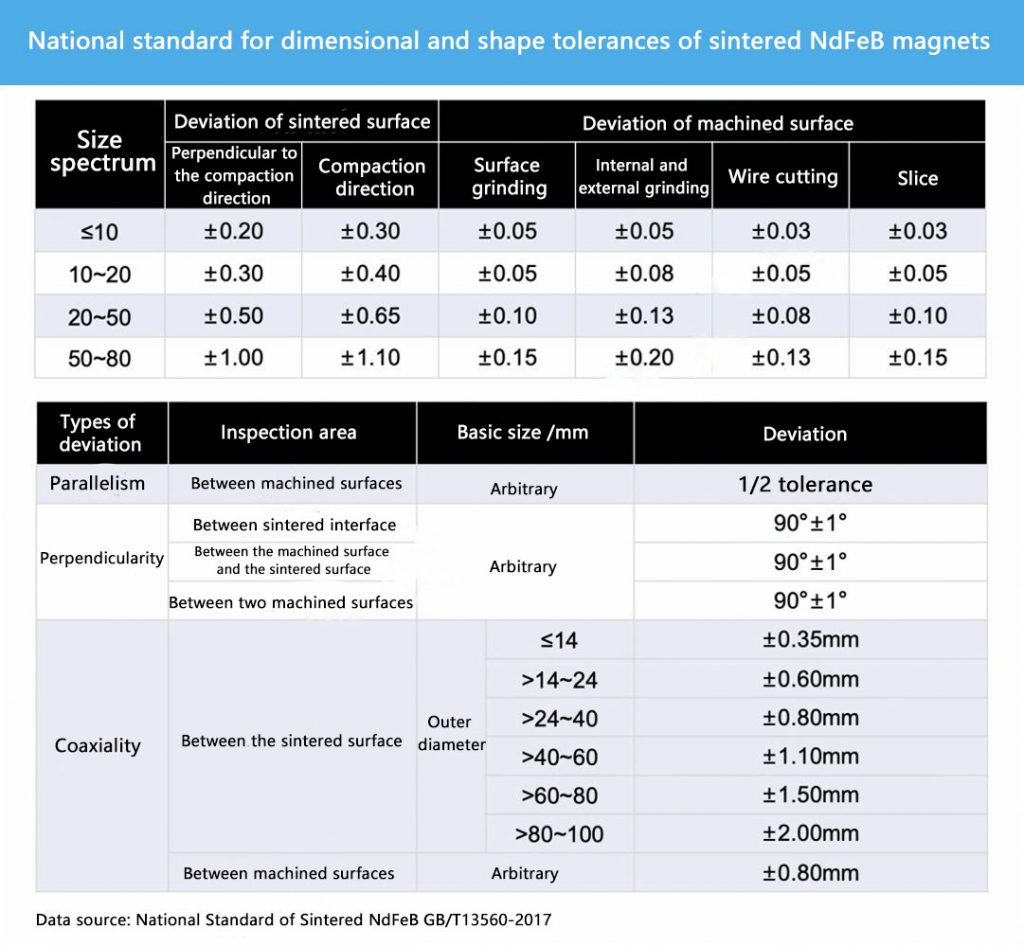

7. Dimensional tolerance

The permissible variation in the size of a workpiece during machining. It is acceptable for magnetic materials to have some dimensional differences within the specified tolerance. Tolerance is defined as the absolute value of the difference between the maximum and minimum limit sizes, or the difference between the upper and lower deviations.

8. Geometric tolerance

Form and position tolerances, also known as geometric tolerances, include form tolerances and location tolerances. Any part is composed of points, lines, and surfaces, which are called features. The actual features of a machined part always have errors relative to the ideal features, including form errors and location errors. These errors affect the function of mechanical products, so corresponding tolerances should be specified and marked on the drawings according to the specified standard symbols.

9. Neutral Salt Spray (NSS) test

Salt spray testing is an environmental test that uses artificially simulated salt spray conditions created by salt spray test equipment to evaluate the corrosion resistance of products or metal materials. There are two main types of salt spray tests: neutral salt spray (NSS) and acidic salt spray (CASS). The difference between the two lies in the standards they comply with and the test methods employed. Sintered neodymium iron boron undergoes neutral salt spray testing using a continuous spray method according to national standards. The test conditions are as follows: temperature of 35±2°C, 5±1% NaCl solution (by mass), and the pH of the collected salt spray solution is between 6.5 and 7.2. The angle at which the specimen is placed can affect the test results. The specimen surface should be inclined at an angle of 45±5° within the salt spray chamber.

10. Humidity and heat test

Sintered NdFeB wet heat test is a method to accelerate the evaluation of the sample’s resistance to degradation under humid and hot conditions. The sample is subjected to a high unsaturated water vapor pressure for an extended period. The test conditions are: temperature 85°C ± 2°C, relative humidity 85% ± 5%, and distilled water or deionized water is used for humidification. The severity level is 1, which is 168 hours.

11. Pressure Cooker Test(PCT)

Pressure cooker tests are generally referred to as pressure cooker boiling tests or saturated steam tests. The main purpose is to place the test samples in a harsh environment with high temperature, saturated humidity, and pressure to test the sample’s resistance to high humidity.

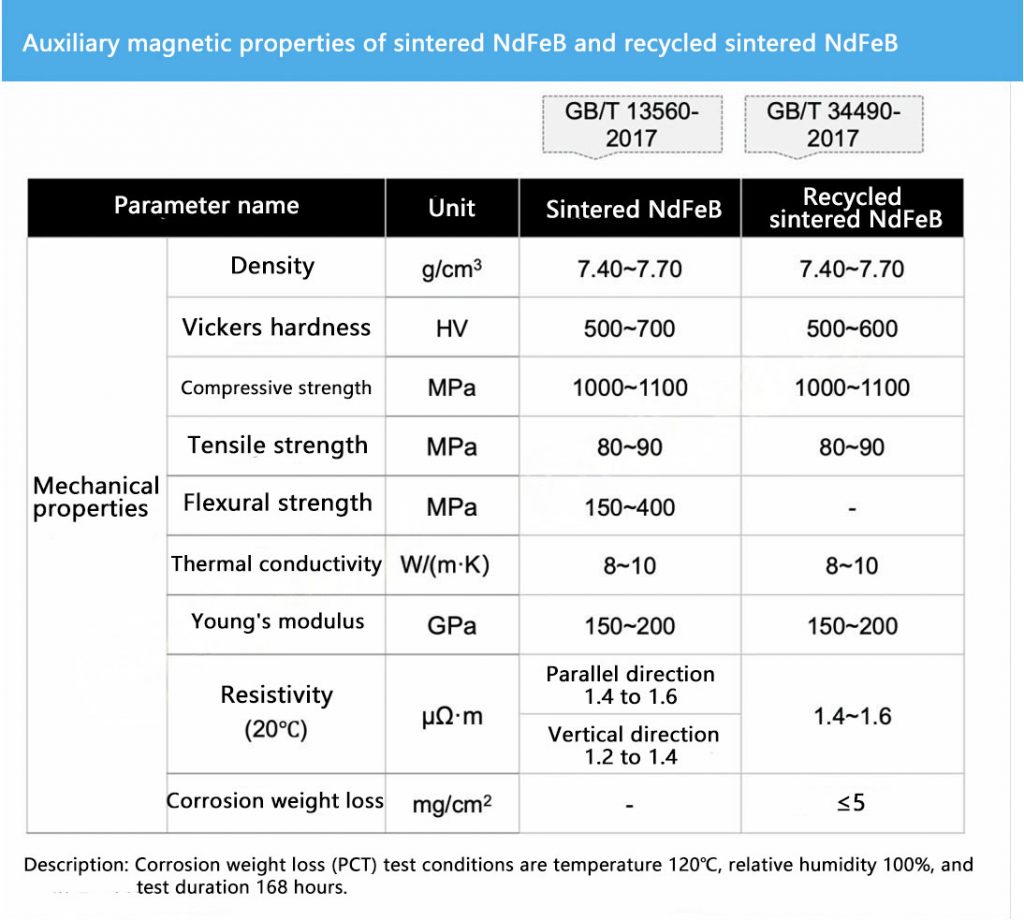

12. Hardness and strength

Hardness refers to a material’s resistance to localized deformation when a harder object is pressed into its surface. It is a measure used to compare the relative hardness of different materials. Higher hardness indicates a stronger resistance to plastic deformation.

Strength refers to the maximum ability of a material to resist external forces. Depending on the type of external force, strength can be categorized into:

- Tensile strength: the maximum stress a material can withstand when under tension.

- Compressive strength: the maximum stress a material can withstand when under compression.

- Flexural strength: the maximum stress a material can withstand when subjected to bending.

13. Crack resistance

Typically reflecting the strength of crack propagation in a material, fracture toughness is measured in units of MPa·m1/2. To test the fracture toughness of a material, tensile testing machines, stress sensors, extensometers, dynamic strain amplifiers, etc., are required. Additionally, the specimen needs to be prepared in a thin sheet form.

14. Impact strength (impact fracture toughness)

Impact strength (impact fracture toughness) reflects the energy absorbed by a material during the fracture process under impact stress, with units of J/m². The measured value of impact strength is highly sensitive to the size, shape, processing precision, and testing environment of the specimen, leading to a large dispersion in the measured values.

15. Bending strength

Bending strength is a measure of a material’s resistance to fracture under a three-point bending load. Due to the ease of sample preparation and measurement, it is the most commonly used method to describe the mechanical properties of sintered NdFeB magnets.