Why NdFeB Magnet are Critical for High-Performance Electric Motors

Neodymium iron boron NdFeB magnets (NdFeB) is a super strong magnet that’s used in many types of electric motors. These magnets are incredibly powerful and efficient. They help motors to produce more power, run more smoothly, and be more reliable. As technology keeps improving, we’ll see NdFeB magnets being used in even more ways.

1.Basic Properties of NdFeB Magnet

- High Energy : NdFeB magnets possess an exceptionally high energy product, enabling them to generate a stronger magnetic field in a smaller volume compared to other magnetic materials. This translates to higher efficiency and power density in electric motors.

- Excellent High-Temperature Stability: These magnets exhibit remarkable stability at elevated temperatures, making them ideal for motors operating in high-temperature environments.

- Low Temperature Coefficient: NdFeB magnets have a low temperature coefficient, meaning their magnetic properties remain relatively unchanged even when exposed to varying temperatures. This is crucial for ensuring stable motor performance across a wide temperature range.

- High Coercivity: The high coercivity of NdFeB magnets provides excellent resistance to demagnetization, ensuring a stable magnetization direction and enhancing motor reliability and durability.

- Versatility: NdFeB magnets are available in a wide range of grades, allowing for customization to meet the specific requirements of various motor designs.

2.Application Cases of NdFeB Magnets in Motors

NdFeB magnets find extensive applications in various industrial equipment. Some of the primary application areas include:

Automotive Industry: NdFeB magnets are widely used in electric vehicle drive motors, generators, and braking systems. Additionally, they are employed in automotive applications such as electric clutches, alternators, electronic throttle control systems, and generators.

Industrial Automation: In industrial manufacturing, NdFeB magnets are used in the motors of CNC machine tools, as well as in gripping and handling devices for automated production lines, enhancing production efficiency and precision.

Aerospace: NdFeB magnets are utilized in satellite attitude control actuators and aircraft motors, leveraging their high magnetism and stability.

3.Key Considerations for Choosing NdFeB Magnets

The following key considerations are crucial when choosing NdFeB magnets for high-performance motors:

Material selection: NdFeB magnets come in two main types: sintered and bonded. Each type offers unique properties and is suitable for different applications. Sintered NdFeB, renowned for its exceptionally high energy product, is the industry standard for demanding applications.

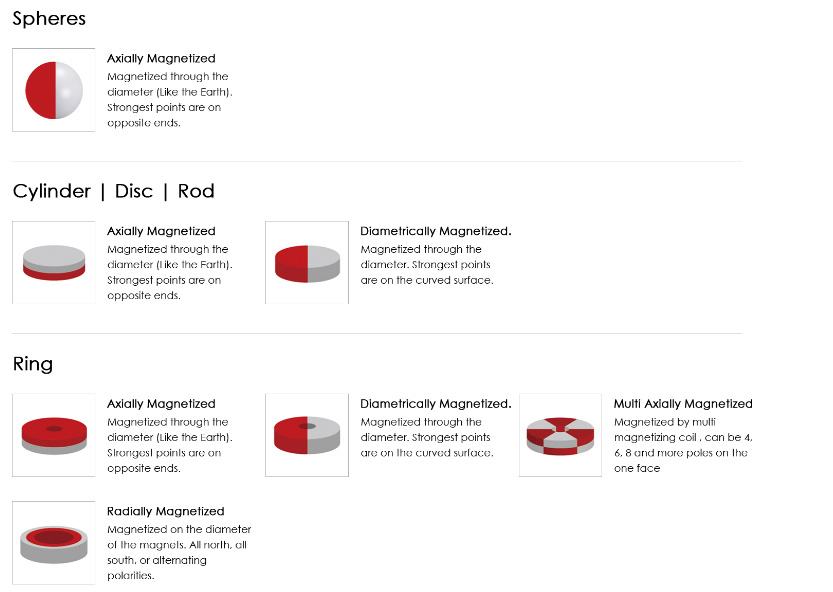

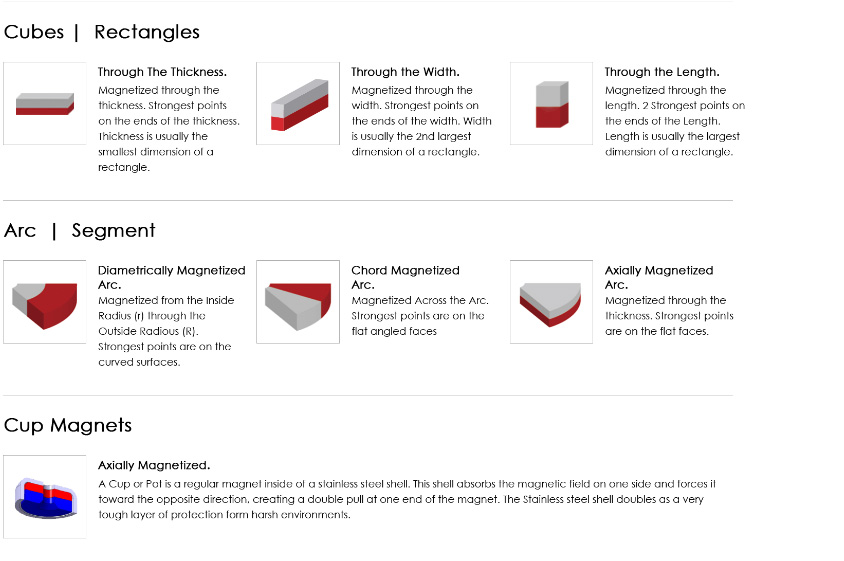

Size and shape: NdFeB magnets can be customized into various sizes and shapes, such as disks, blocks, rings, and arcs. Suppliers of NdFeB magnets can also produce non-standard shapes according to customer specifications.

Magnetic grade: NdFeB magnets come in various grades such as N35, N40, N42, N45, N50, and N52. These grades represent the magnetic performance of the magnets, allowing for the selection of the appropriate grade based on specific application requirements.

Temperature resistance: NdFeB magnets come in various temperature grades such as N, M, H, SH, UH, EH, and AH, each representing different levels of temperature coefficient and maximum operating temperature. When selecting a magnet, the operating temperature should be considered to ensure the magnet maintains good magnetic stability under high temperatures.

Magnetization direction: The choice of magnetization direction has an important influence on the magnetization efficiency and directionality of the magnet, and needs to be determined according to specific application requirements.

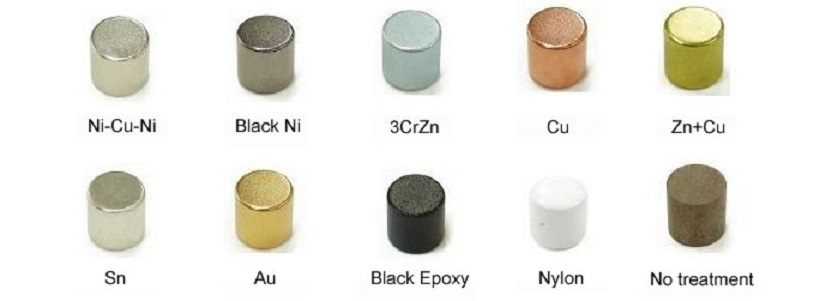

Coating selection: A good coating can prevent magnets from rusting and corroding, extending their lifespan. Common coating options include nickel plating, copper plating, and silver plating, with the specific choice depending on the application environment.

By comprehensively considering all of the above factors, the most suitable neodymium iron boron magnet for a specific application can be selected to ensure optimal performance under various conditions.

4.Future Prospects

In recent years, the market for NdFeB magnets in motor manufacturing has experienced sustained growth, driven by several key factors:

New Energy industry: NdFeB magnets play a crucial role in the new energy industry, including wind power generation, hybrid electric vehicles, and electric vehicles. Their high energy density makes them indispensable components in wind turbines and electric vehicle motors.

Manufacturing industry growth: The application of NdFeB magnets in automation equipment and industrial robots is also expanding. Their superior magnetic properties contribute to improved efficiency and precision in these devices, driving advancements in manufacturing.

Technological innovation and upgrades: With advancements in materials science and processing technology, the performance of NdFeB magnets continues to improve. The development of new alloy materials and advanced manufacturing processes will enable NdFeB magnets to exhibit even better performance in terms of high temperature resistance, corrosion resistance, and high energy density.

Environmental protection and sustainable development: Strict environmental regulations have prompted increased attention to environmentally friendly measures and sustainable development strategies in NdFeB magnet production. Compared to traditional lead-based motors, motors using NdFeB magnets are more environmentally friendly as they do not contain harmful substances.

The industrial motor market is substantial, but the current application of NdFeB magnets in this sector is still relatively small. The future prospects of NdFeB magnets in this field will depend on factors such as the implementation of relevant policies and measures.